Extraction, the process of capturing the olfactory essence of the raw material, appears in the form of enfleurage, particularly in Egypt. It is practiced in two ways: cold and hot.

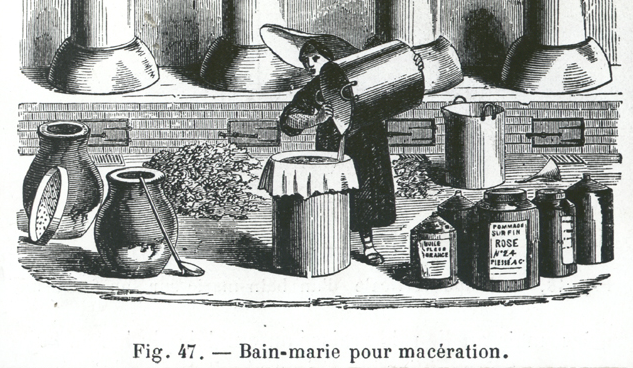

Hot enfleurage is the result of infusing flowers, or other olfactory materials, in a fatty substance then heated to a temperature between 40 and 60 degrees, depending on the material extracted. The whole is then mixed at high frequency in order to saturate the fat with aroma. The result obtained, called ointment, will be filtered and decanted with alcohol, giving what is called absolute.

Performed cold, enfleurage consists of applying fat to a long glass plate, on which the flowers are then delicately placed. The whole mixture will then be filtered and decanted in the same way as for the first process.

Hot enfleurage, © Grasse City Museum | Cold enfleurage, © Fragonnard Museum

Technical and industrial developments have democratized distillation, an ancient process that was little used until then. The system is as follows: a still is filled with the flower or plant from which the essence is to be extracted.

This tank is then heated with water. The steam released is evacuated through a connected pipe and then condensed to obtain an essential oil. Floral water is then obtained after cooling this oil, by collecting the resulting condensation.

Expression is a form of extraction specific to citrus fruits. It is the peel that contains all the olfactory power of the fruit. Previously carried out manually, it consisted of moistening the inner skin of the citrus fruit, from which the pulp had previously been removed.

After resting for more than 8 hours, this moistened skin will be pressed onto a sponge, which will capture its essence. After decanting, the essence will then be collected in a vase. Now industrialized, expression can also be carried out with whole fruits; the juice and essence will then be separated by centrifugal force.

A PROCESS THAT IS NOW INDUSTRIAL

The progressive "industrialization" leads to the development of volatile solvent extraction. After drying the plants, they are placed in large vats, where grids are spread across the entire height to allow them to be arranged. After being immersed several times in these vats filled with Benzene, the plants are then wrung out and removed from the vats. The solvent, having captured all their olfactory molecules, will then be heated, and its evaporation will give a paste called concrete. Washed and purified with alcohol, then filtered, the concrete is transformed into absolute, a pure material essential to the development of the perfume and perfectly translating the olfactory qualities of the berry.

Image: © François Kollar, 1963

To date, the most precise process in terms of extraction and purity of result is that carried out by supercritical CO2. It imposes a first constraint; CO2 is only slightly soluble in water, and the latter acidifies the olfactory environment. It is therefore a process intended mainly for dry plants, fresh plants having a high water content, involving technical drying and greatly extending the time taken for extraction. Unlike the previous processes mentioned, which mostly involve exploitation of the material by heat, which affects the plant. CO2 extraction is carried out at 30°C. The gas used is extracted from agricultural sectors for the most part, or it is considered as waste. Placed in a cylindrical tank, equipped with a filter from side to side, the raw material from which the essence is to be extracted is immersed in pressurized CO2, whose state is between liquid and gas. Upon contact, the essential oil of the plant is dissolved in the CO2, and will finally be extracted when the pressure is released: the CO2 returns to its gaseous form, and separates from the olfactory molecules which are exfiltrated through a conduit.

DISCOVER THE COLLECTION